South Dakota School for the Blind and Visually Impaired

Aberdeen, SD

- Tagged under:

- K-12

Metrics

- Size:

- 50,043 sf

- Cost:

- $13.6 Million

- Specialisms:

- Acoustics, Commissioning, Enclosures, Green Building Certification, Smart Buildings

Located in Aberdeen, South Dakota adjacent to the Northern State University campus, South Dakota School for the Blind and Visually Impaired (SDSBVI) has served students with a range of visual impairments in the same facility for nearly 60 years. When moving the school became necessary, a new facility was conceived. Now, with a customized design, generations of students will have a facility conducive to learning and exploring.

When BranchPattern was brought on as the commissioning provider for the new facility, our team helped administrators establish priorities for the commissioning plan and provided measurable benchmarks to guide the design team. By bringing forward a human-centered approach, we helped shape the school’s commitment to occupant well-being and comfort.

With those priorities in mind, BranchPattern created and tracked performance of metrics that can highly impact student performance and comfort: air quality, thermal comfort, lighting and acoustics. For example, our team understood that noisy HVAC systems can add another barrier to academic learning; poor lighting design provides an opportunity to optimize student vision and make navigating the building easier.

BranchPattern created a supportive student experience by focusing on three service areas: air quality assessments, monitoring based commissioning and enclosure commissioning.

Air Quality Assessments

We provided air quality assessments to confirm that air quality targets were achieved after the project was completed. Using industry accepted sampling methods, we collected air samples from both the residential and academic parts of the building, and sent them to a lab to have them inspected for contaminants. As a result, we found that there were not chemicals off-gassing in the building, and that the mechanical system was working properly.

Monitoring Based Commissioning

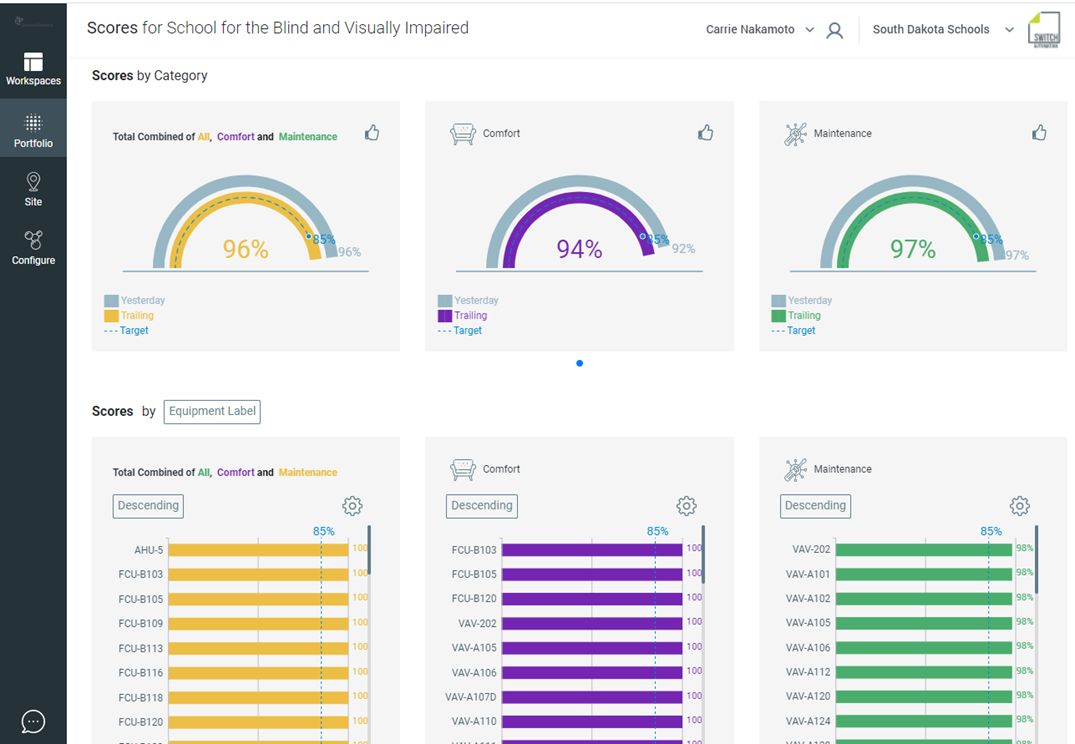

Because the SDSBVI facilities team is fully responsible for running the facility, through the continuous tracking of the performance of the building, our team is helping SDSBVI staff actively identify problems. For example, due to setpoint issues where the air handlers were not operating on the appropriate schedule, our team showed staff how to blow out the strainers. Additionally, it was found during calibration of the CO2 sensors that some of the systems weren’t reading properly. The software platform we delivered for the service helped identify issues that saved maintenance and energy costs.

Enclosure Commissioning

We validated the continuity of the air, thermal and weather barriers for the facility, and tracked these issues throughout the project. We then provided thermal image scans to confirm our strategies were effective. Because we identified and closed all issues of concern, there were far fewer issues to address during the warranty period.